Optimum result in belt grinding can only be achieved, when grinding belts and contact wheels are matched for the specific process.

Only the correct choice of contact wheel enables the belt to unfold all its potential, in respect of stock removal, felxibility and life time. For fine grinding with fine grit, soft contact wheels are used. For rough applications, a sturdy, medium hard to hard contact wheel is the correct choice.

Grooves on the contact wheel support the grit for better impact and stock removal. At the same time, they can help to clean the belt from griding dust.

For very fine applications, smooth contact wheels with a flat surface are the right choice.

Type A66

EP-Rubber-Contact-Wheel, smooth tyre on aluminium-core

Ideal for heavy duty grinding with more aggressive grits on “J” and “X” abrasive belts.

– Ø 50 – 500 mm

– width 10 – 250 mm

– hardness from 40° to 90° Shore A (very soft to very hard)

Applications:

pre-to normal grinding

also used as idler or support roll

dry or wet grinding

hand, automatic and robotic use

Alternative Type A97: Rubber, smooth, 30° Shore

Type A77

EP-Rubber-Contact-Wheel, grooved tyre on aluminium core

This contact-wheel has a particular high stock removal potential throughits grooving pattern and use with “X” type

abrasive belts.

– Ø 50 – 500 mm

– width 10 – 250 mm

– hardness from 40° to 90° Shore A (very soft to very hard)

Applications:

normal to heavy duty grinding

marked stock removal

can also be used as an idler or support wheel

wet and dry grinding

hand, automatic and robotic use

Alternative Type A970:Rubber, grooved, 30° Shore

Type A8 Plastidur

EP-Plastidur-Contact-Wheel, with smooth tyre on aluminium core

Exceptional abrasiveness, oil and fat resistant, extended

life compared to rubber; ideal for heavy duty grinding with coarsegrit types on “J” and “X” abrasive belts.

– Ø 50 – 500 mm

– width 10 – 300 mm

– hardness Shore A 50°= medium, 80°= hard, 95°= very hard

Applications:

for exceptional heavy duty grinding and stock

removalpre to normal grinding wet and dry

use hand, automatic and robotic use

Type A11 Plastidur

EP-Plastidur-Contact-Wheel, grooved tyre on aluminium core

Exceptional abrasiveness, oil and fat resistant, extended life compared to rubber; the contact-wheel has a particular high stock removal through its grooved surface and use with “X” abrasive belts of coarse to medium grits.

– Ø 50 – 500 mm

– width 10 – 300 mm

– hardness Shore A 50°= medium, 80°= hard, 95°= very hard

Applications:

for exceptional heavy duty grinding and stock

removalpre to normal grinding wet and dry use

hand, automatic and robotic use

Type A9 Plastiflex

EP-Foam-Contact-Wheel smooth tyre on aluminium core

High elasticity, oil and acid resistant foam contact wheels with good adaptation to contoured surfaces, quiet running, profiled

parts, for use with “J” abrasive belts.

– Ø 100 – 450 mm

– width 20 – 200 mm

– hardness extra soft, soft or medium

– tyre height 20 mm

Applications:

pronounced rounded and profiled parts

sanitary fittings (faucets), handles, fine to very

fine grinding, contoured grinding wet and dry

use hand, automatic and robotic use

Type A90 Plastiflex

EP-Foam-Contact-Wheel, grooved tyre on aluminium core

High elasticity, oil and acid resistant foam contact wheels withgood adaptation, more stock removal than A9 on soft metals,

belt clean on light vibration, for use with “J” abrasive belts.

– Ø 100 – 450 mm

– width 20 – 200 mm

– hardness extra soft, soft or medium

– tyre height 20 mm

Applications:

pronounced rounded and profiled parts

sanitary fittings (faucets), handles, fine

to very fine grinding, contoured grinding

wet and dry use hand, automatic and robotic use

Type A10 Plastiflex

EP-Foam-Contact-Wheel smooth tyre on aluminium core

High elasticity, oil and acid resistant foam contact wheels with exceptional adaptation to contoured, profiled parts, for use

with “J” abrasive belts; use of a 40 mm tyre height increases markedlythe elasticity of the contact wheel.

– Ø 100 – 450 mm

– width 20 – 200 mm

– hardness extra soft, soft or medium

– tyre height 40 mm

Applications:

pronounced rounded and profiled parts

sanitary fittings (faucets)

handles

fine to very fine grinding

contoured grinding wet and dry use hand

automatic and robotic use

Type A100 Plastiflex

EP-Foam-Contact-Wheel grooved tyre on aluminium core

High elasticity, oil and acid resistant foam contact wheels with exceptional adaptation to contoured, profiled parts, more

stock removal than A10 on soft metals, belt clean on light vibration,for use with “J” abrasive belts, use of a 40 mm tyre

height increases markedly the elasticity of the contact wheel.

– Ø 100 – 450 mm

– width 20 – 200 mm

– hardness extra soft, soft or medium

– tyre height 40 mmapplications: pronounced rounded and profiled parts

Applications:

sanitary fittings (faucets), handles, fine tO

very fine grinding, contoured grinding wet

and dry use hand, automatic and robotic use

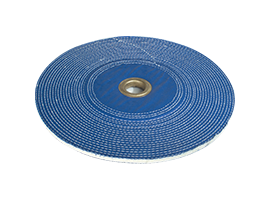

Type A1 fine grinding

EP-Cotton-Flap-Contact-Wheel on aluminium core

Vibration-free grinding, with “J Flex” abrasive belts of fine grit; no shadow or tints, blended ground surface; noiseless running as a result of smooth textile tyre

– Ø 100 – 450 mm

– width 300 – 100 mm

– hardness soft, medium and hard

Applications:

fine grinding of rounded or flat steel or brass

parts, surgical instruments, dry grinding,

manual operation

Type A14 – Permaflex

EP-Foam-Flap-Contact-Wheel on aluminium core

High elasticity for optimal adaptation to work part profile, oil and acid resistant foam flaps, for use with “J” abrasive belts.

The configuration of the 10 mm wide flaps ensures excellent cooling and utilization of the abrasive belt. The tyre adapts to

any work piece without excessive pressure thus allowing for optimal results and contact-wheel lifetime.

– Ø 150 – 450 mm

– width 30 – 150 mm

– hardness extra soft, soft or middle

– tyre height 20 to 45 mm high

Applications:

super, fine grinding of profiled parts cool

grinding, wet or dry use, manual,

automatic or robotic use

Type A15

EP-Extra-Flexible-Cotton-Foam-Flap-Contact-Wheel on aluminium core Foam flaps laminated with cotton cloth allow for use with “J”

abrasive belts. Exceptional elasticity for optimal adaption to work part.

– Ø 150 – 450 mm

– width 30 – 150 mm

– hardness soft, medium

– tyre height 35 – 50 mm high

Applications:

fine grinding of highly profiled

components, dry grinding, for manual,

automatic or robotic use

Type A12

EP-Flap-Contact-Wheels

Cotton or foam flaps, or alternating flaps of rubber and foam,or leather and foam, flexibly mounted on steel bolts. As

centrifugal material a foamed flap (synthetic) is used. Cloth supports the foam. To increase hardness, various materials

are used as fill material. Also various numbers of flaps can be chosen, to vary hardness.

– Ø 350 – 800 mm

– width 20 – 100 mm

– number of flaps 12/16/24/30/48

– type of flaps: cloth only, cloth/foam, cloth/foam + rubber, leather + foam, cloth/foam/leather

Type A20

EP-Layer-Contact-Wheels

Layers of fabric (supporting material) and foam (centrifugal material). The centrifugal material is released by opening the

seams (1 to 3 seams). The extent of the seam opening is generally determined by the profile of the part being ground (a

little centrifugal material means a hard contact area, a lot of centrifugal material means a very soft contact area).

– Ø 350 mm

– width 5 – 20 mm

– materials textile only or textile/foam mix

Applications:

tight profiles, edges, small passages

manual or robotic use

EP-ONE WAY Contact Wheels

All contact wheels with aluminium core can also be supplied with a synthetic core. Main advantage of the synthetic core is,

the cost savings compared to that of an aluminium core. This makes it particularly suitable, if an aluminium core will not be

re-used due to high shipment costs to the re-covering company. Also, due to the one way system, tedious collection and

administration of old cores can be avoided. These special contact wheels are only available in standard sizes.

Please ask for your specific requirements.

– EP-Type A66/K

– EP-Type A77/K

– EP-Type A8/K

– EP-Type A11/K

– EP-Type A9/K

Advantages:

1) Low costs for savings on aluminium core

2) Reduction of logistic costs

3) Reduction of administration cost for used aluminium cores

4) Reduction of wear on machine bearings and spindles due to light weight

Special types

Idler Rollers, small contact-wheels, different tyre hardnesses on one roller, axles spindles, with or without bearings, different elastomers, special grooving patterns, can all be obtained on inquiry and receipt of an exact drawing.