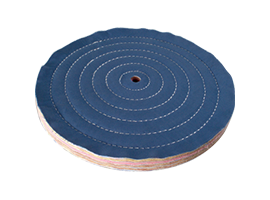

EP-Polishing Buffs

Outside diameters from 60 to 1000 mm.

The 45° cut to circumference allows for a consistent wear of the buff with very little dust production.

Dressing

Balancing

Impregnation

Folding

Rule-of-thumb

– closed, dense folds = firm to hard buff (corrugated wave buff D1WP and D1B) for aggressive pre-polishing

– normal folds = medium to hard, well ventilated standard buffs (type D1A/K)

– open folds = soft, excellent ventilation and the ability to submerge the work piece deep into the polishing roll (type D1C spiral)

Centers

Solid Cardboard Centers

Keyways, hexagonal and round bores are all possible.

EP Cotton Fabrics Used in Polishing Buff Manufacture

NKG: medium, standard fabric for polishing and end-finishing, non-ferrous metals, steel or stainless steel

NKW: medium dense, hard wearing fabric for polishing, non-ferrous metals, steel or stainless steel

NF: medium dense fabric for more aggressive polishing, non-ferrous metals, steel or stainless steel

C31: medium hard fabric for aggressive polishing, non-ferrous metals, steel or stainless steel

C32: hard pre-polishing fabric for intensive stock removal up to mirror finish, non-ferrous metals, steel or stainless steel

C33: very hard pre-polishing fabric, high stock removal, non-ferrous metals, steel or stainless steel

852: yellow treated fabric, robust stock removal, with a special mirror polishing effect, steel or in particular stainless steel

930: pink treated fabric, medium hard, good stock removal, non-ferrous metals, steel or stainless steel

931: pink treated fabric, more flexible, good stock removal, non-ferrous metals or stainless steel

932: very robust but soft and flexible, very long lasting, non-ferrous metals

Type D1A/K

EP-Standard-Polishing-Buff

Cotton cloth cut at 45°, held in a steel-clench-ring, light wavy and irregular folding; manufactured in all cotton types

– Ø 150 – 960 mm

– width 16 – 24 mm

– ply 8 – 24

Applications:

polishing of flat parts without any marked contours, metal, wood, synthetic material or varnish surfaced,

automatic and manual use

Type D1B/K

EP-Polishing-Buff Coarse-Folding

Cotton cloth cut at 45°, held in a steel-clench-ring or steel ring tuck folding, this fold type is more robust than the D1A/K fold; despite denser construction the buff reacts elastically to fit most contours, manufactured in all cotton types

– Ø 350 – 500 mm

– width appr. 20 to 25 mm

Applications:

single buffs for edges, mounted as buff sets, distanced with spacers for flexible roller assembly, appropriate for flat or profiled parts

mostly non-ferrous metals

Type D1C

EP-Polishing-Buff, Spiral-Folding

Cotton cloth cut at 45°, held in a steel-clench-ring, ring-center or card-board-center; further stability with additional round stitching; flexible tuck folding manufactured in all cotton types

– Ø 150 – 1000 mm

– width appr. 20 – 25 mm

– ply 4 x 4 or 8 x 2

Applications:

universal buff for all components and metals on automatic and manual machinery, robotic applications, CNC polishing machine, most popular as buff sets for sanitary fittings and faucets

Type D1 WP

EP-Polishing-Wave-Buff

Cotton cloth cut at 45°, held in a steel-clench-ring, ring-center or card-board-center; constant fixed number of folds, most aggressive fold, manufactured in all cotton types certain limitations with treated materials

– Ø normal density 300 – 430 mm high densitiy 400 – 600 mm

– width 25 mm

– density normal and high

Applications:

cooking pots and hollow-ware, tubes, mounted to allow for homogeneous polishing without gaps or lines, especially used as a single buff on edges (electric iron-bases, cooking-pots)

Type D1A/K Mini

EP-Mini-Polishing-Buff

45° cut cotton cloth in steel-clench-ring; slight wave and irregular folding; manufactured in all cotton types

– Ø 50 – 250 mm

– bore 14/6, 19/6, 24/6 and 32/6, hexagonal in mm

– width 10 – 15 mm

– ply 6 – 12

Applications:

cutlery industry, electric hand-held devices

Type D1A/KS

EP-Mini-Polishing-Buff-Roll

45° cut cotton cloth with plastic center;

slight wave and irregular folding;

convex or concave profiles

manufactured in all cotton types

– Ø 70 – 160 mm

– bore 14/6, 19/6, 24/6 and 32/6, hexagonal in mm

– width 15 – 120 mm

Applications:

cutlery industry

Type D1C/KK

EP-Polishing-Buff-Roll, Spiral Folding

45° cut cotton cloth with plastic center;

pronounced, flexible folding, face profiled or straight;

manufactured in all cotton types, except stiff treated materials

– Ø 150 – 250 mm

– bore 19/6, 24/6 and 32/6, hexagonal in mm

45KN, 70KN mm with keyway

– width 20 – 100 mm

Applications:

cutlery industry

Type E

EP-Shirting and Coloured Material Polishing Discs

Manufactured from piece material and half leafs or discs in a wedge shape which work more effectively

– Ø 200 – 1000 mm

– Neubunt soft and coloured

– Shirting medium

– drell mixture firm batist, shirt popline

Applications:

manual and run-through-polishing-machines

Type E

EP Polishing Discs

Full leave, simple leaf construction,

additional stitching allows for further stability, high quality cotton used,

punched full leaves from 100 to 1000 mm Ø

– quality NK dense grey cotton

– quality NFR finett-flanel, roughened, soft material

Applications:

robotic and CNC machinery, automatic machinery or manual use