Experience has shown, that the most optimal belt-grinding is only achieveable on a high quality, specifically chosen contact wheel.

The wrong choice or incorrect use of the contact wheel leads to poor belt performance and subsequent low quality grinding results.

Hardness

The hardness of rubber or polyurethane contact wheels is measured in

degrees shore A.

30° Shore A = very soft

40° Shore A = soft

60° Shore A = medium

80° Shore A = hard

90° Shore A = very hard

Plastiflex- and Permaflex contact wheels.

Hardness quality: “medium”, “soft” and “extra soft”.

Rubber, PU, Plastiflex and Permaflex coatings

These materials are ideal for dry, wet or oil grinding with various grit sizes and belt types, X or J belts.

Polyurethane Coatings

This material is resistant to mechanical wear,oils and fats.

50° – 95° Shore A

Types A8, A11

Rubber Coatings

This material is oil and acid resistant

30° – 90° Shore A

Types A66, A77, A970

Foam Coatings

Mild grinding, oil and water resistance.

These soft Plastiflex and Permaflex contact wheels show minimum wear on extended use. Excess pressure leads to heating of the coating with consequent melting, this should be avoided at all costs.

Types A9, A90, A10, A100, A14, A15, A16

Textile Coatings

Textile coatings are ideal for dry use and particulary fine processing. The advantage of textile coatings is minimum vibration and hardly any noise in running (very low decibel).

Type A1

Recycling

Rubber rollers and contact wheels with aluminium cores can be economically recovered with a new coating. Contact-wheels with plastic centers cannot be re-used and re-covered. For this reason we prefer to manufacture contact wheels with aluminium cores, where re-cycling is possible.

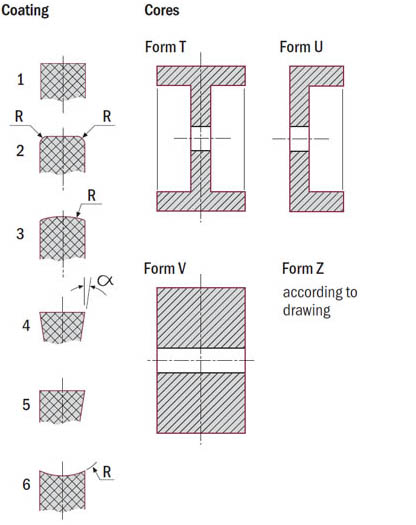

Grooving

The deeper and wider the grooving the more aggressive the effect of the abrasive grit and the higher the stock removal. Flat coated contact wheels are more ideal for finer grit sizes.

grooving No. 2: fine, uniform grooving for fine grinding

grooving No. 3: standard grooving for universal grinding (most commonly used grooving)

grooving No. 6: “saw-tooth” grooving for coarse grinding

Hardness

The harder the contact wheel the greater the stock removal. The contact wheel should be as hard as work part contours allow. Highly contoured work parts require softer contact wheels.

Coated Abrasive Belts

Harder contact wheels, 60°–90°, are used with less flexible X-backed cloth abrasive belts. Softer contact wheels are used with flexed or softer J-backed cloth abrasive belts.

Contact Wheel Forms